The precision and quality of the final products largely depend on the accuracy of measurements and the ability of measurement equipment to perform them in the most efficient and precise manner possible. And this is precisely what Innovalia Metrology brings with its M3 Hybrid solution, which combines machinery, sensors, and software to optimize the quality control process.

The Versatility of M3 Hybrid: Contact and Non-contact Measurements Combined

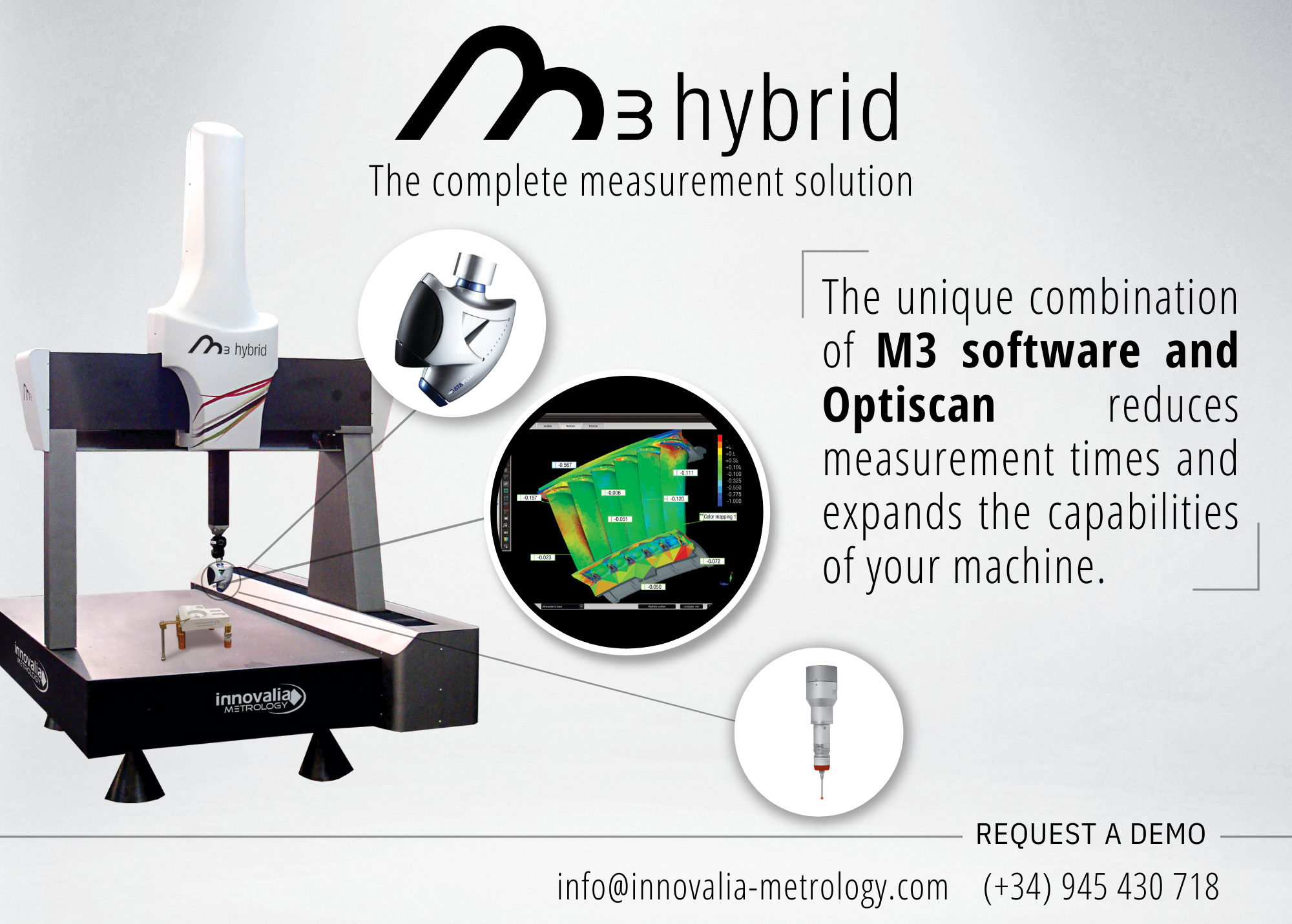

M3 Hybrid is a comprehensive measurement system that offers the possibility of combining both contact and non-contact measurements. With its latest updates, it stands out as a simple, complete, and highly productive measurement tool. The combination of probes and the seamless integration with the M3 software allows the system to perform precise and detailed measurements on parts of any shape and size, making it an ideal solution for a wide range of applications in the industry. At the same time, the ability to automate the sensor exchange thanks to its integrated interchangeable frame makes complete hybrid measurement programs simpler and faster. Additionally, the probe management function accurately simplifies the setup and calibration of the probes.

Adaptability in Challenging Environments

One of the most notable features of M3 Hybrid is its ability to adapt to different work environments. The system can be used in high-demand industrial environments where measurements need to be taken under adverse conditions such as high temperatures, vibrations, and dust. It can also be used in laboratory environments where precise and detailed measurements are required. M3 Hybrid is designed to withstand challenging conditions and deliver accurate results consistently. It’s robust construction and advanced technology allow it to perform effectively even in harsh environments. Additionally, the system is designed with user-friendliness in mind, making it easy to operate for both experienced professionals and newcomers. The intuitive interface and streamlined workflows contribute to a seamless user experience.

User-Friendly Design for Seamless Operation

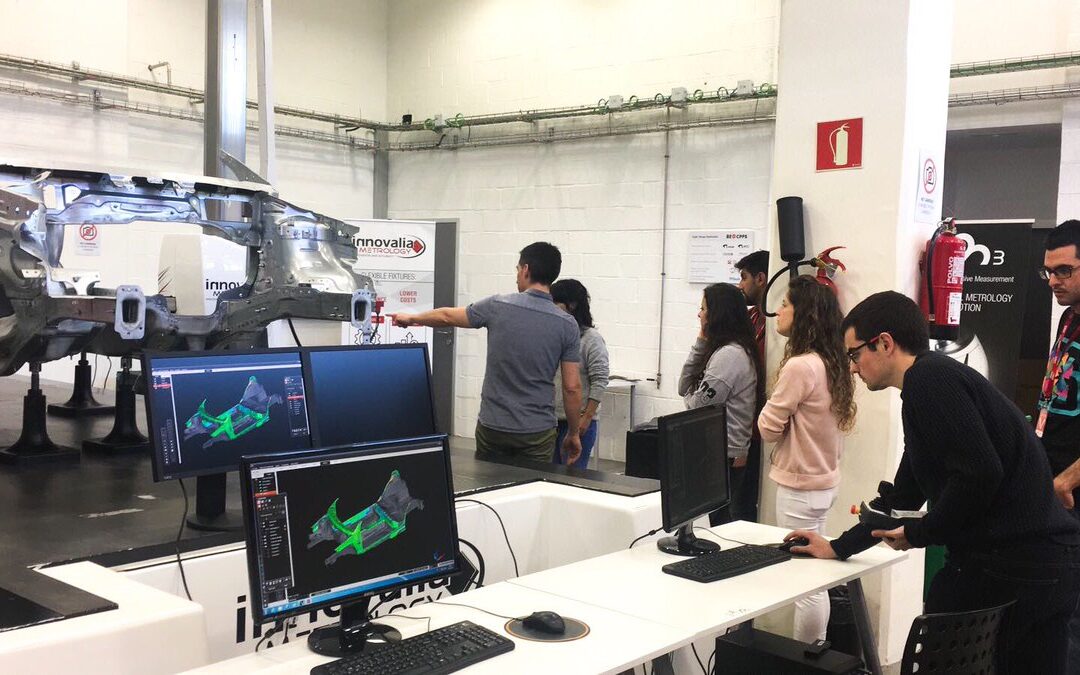

Another essential feature of the M3 Hybrid is its ease of use. The M3 software has been designed to be intuitive and user-friendly, allowing operators to perform precise and efficient measurements without the need for specialized training. The system also offers the ability to automate measurements. Additionally, the system has a graphical user interface that provides a clear and detailed visualization of the measurements taken, as well as the extraction of reports using predefined and customizable templates. This facilitates the interpretation of results and decision-making.

Visualizing Measurements: Intuitive Interface and Detailed Reports

With M3 Hybrid, operators can immediately assess the quality of the measured parts and identify any deviations or issues. This real-time feedback allows for timely adjustments and corrections, leading to improved productivity and quality control. The ability to make fast and accurate decisions based on instant results enhances the overall efficiency of the measurement process.

Precision and Compatibility: Certified Algorithms and Interoperability

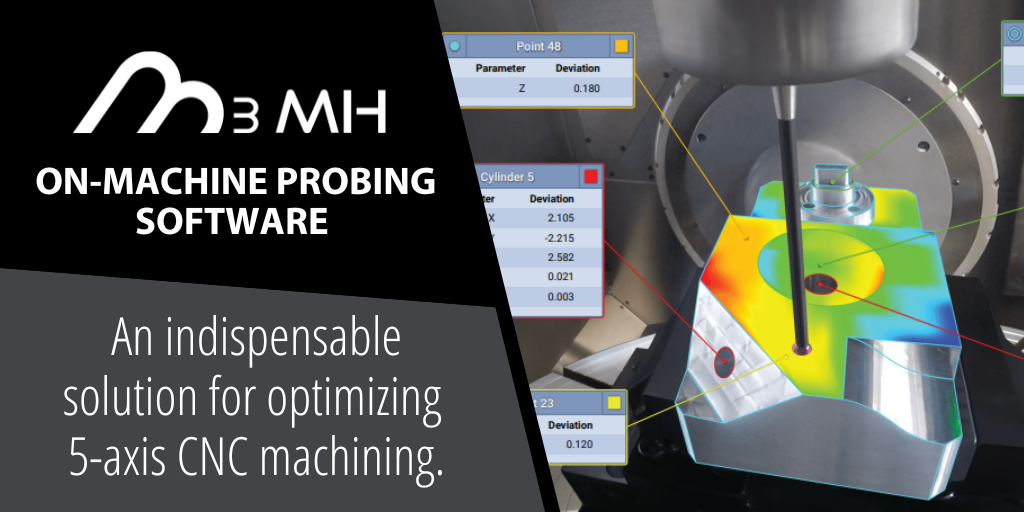

Data collection and analysis are critical processes in manufacturing. Therefore, M3 Hybrid utilizes highly accurate algorithms that have been certified by NIST and PTB to ensure precision. These algorithms are optimized for offline programming and interaction with multiple CAD systems, enabling automatic color mapping and collision detection. In addition, M3 Hybrid’s coordinate axis management system automatically adjusts the CAD orientation to match the probe direction, further enhancing data precision. Interoperability is achieved through various file formats and standards such as QIF, DMO, DMI, and CSV, allowing for greater flexibility in exchanging information between different technological platforms.

By using certified and optimized algorithms, M3 Hybrid ensures the accuracy of measurements, which is crucial for improving manufacturing processes. The system’s compatibility with different file formats and standards enhances its interoperability, enabling seamless data exchange across various platforms. This facilitates efficient collaboration and integration of measurement data into the manufacturing workflow.

High Precision and Repeatability in Measurements

Regarding measurement precision, M3 Hybrid offers high accuracy across a wide range of measurements. The system is capable of conducting measurements with an accuracy of up to 0.001 mm, making it an ideal solution for high-precision applications in the industry. Additionally, the system ensures high repeatability in measurements, ensuring consistency and reliability of the results.

Complete Integration and Customization for Each Application

In terms of integration with other production management tools, M3 Hybrid can be easily integrated, making it a comprehensive and customizable solution for each application. Additionally, the system offers a wide range of accessories and measurement probes, allowing users to adapt the system to different shapes and sizes of parts.

M3 Hybrid is undoubtedly an innovative and efficient solution for dimensional measurement, combining the best of traditional metrology and digital metrology to provide precise and efficient measurements for advanced manufacturing process improvement. Its ability to adapt to different work environments, ease of use, and high precision across a wide range of measurements make it an essential tool for any company seeking to improve product quality and optimize production processes.