– What are the main technological challenges of the sector?

The Basque Country positioned itself as the unskilled and cheap workforce of European industry 25 years ago until different changes began to take place, such as the qualification of production, investment in improvement and different indicators that were marking a clear path towards which is now the Basque Industry. The Basque industry was gradually demanding more investment because it brought more quality and the Basque Country became a clear engine of innovation while some processes moved outside of Spain and Europe. The Industrial sector faces many changes with challenges. Innovation is no longer an option, it is a way to progress and a business strategy for every company that wants to develop.

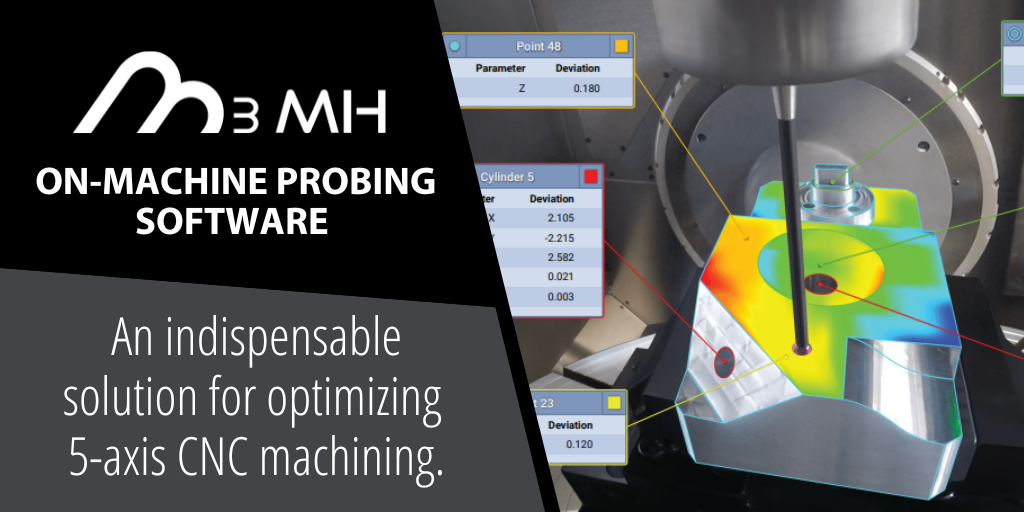

In many cases, innovation is a problem and not the only way to success, a decision that caused the success or failure of many companies in the sector. Today we have the ability to make systems that allow us to move into the future, so I do not think it is a problem of resources, it seems more a problem of attitude or motivation. In metrology, for example, a commitment to incorporate the latest technologies is necessary to be able to add value to the production process, otherwise these companies would have disappeared. Innovalia Metrology is committed to providing online measurement solutions and decision support based on advanced quality control parameters.

– What aspects do you think limit the R+D actions of Basque companies?

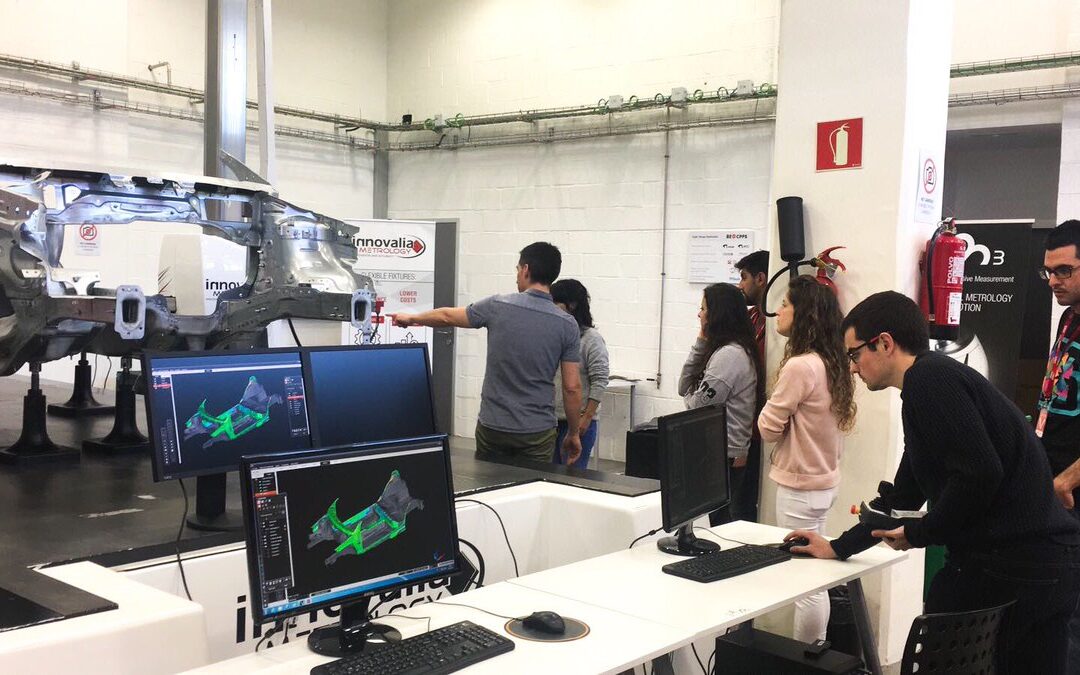

The change of the Basque Industry was due to its own survival. It was in a natural and progressive way that led us to produce in a more optimized way and to give value to the know-how of each company. Today, the industry is more affluent and, in many cases, the response of companies to innovation proposals is “I’m fine”. In addition, most are small companies that cannot invest in R+D. Although not all companies have the same capacity, there are R+D options for small companies that allow them to activate innovative solutions. For example, Innovalia metrology carries out quality control experiments with SMEs in our “zero-defects” manufacturing laboratory located in the AIC, considered as Digital Innovation Hub by the European Commission. This allows to elaborate certain protocols of application of technology and to establish methods of innovation in different points of the industrial production. Thanks to our laboratory, other SMEs can benefit from technology, experience and innovative solutions that have already worked in other companies.

– Do you consider that public support has weakened in recent years? What aspects should be contemplated or promoted by public administrations to help R+D business?

The situation has been complicated in recent years, although we can be satisfied with the level maintained in Euskadi during the crisis as far as R & D aid is concerned. In my opinion, I think we should reduce the bureaucracy because in many cases it discourages us from participating in R & D programs.

– What concrete technological challenges do Innovalia face in the future?

Innovation has always been part of our business strategy. There are companies that invest in innovation, but the creation of the Innovalia Group is the result of innovation and the continuous need that exists in the Group to create technology, internationalize and follow the path towards Industry 4.0.

We are totally immersed in the digital transformation in our situation, from the point of view of consulting and from the generation of digital product to respond to the needs of the industry, from our metrology unit and from our ICT companies.

– What is the leading figure of R+D project in which Innovalia participates and what objectives does it pursue?

Innovalia is part of production projects of zero defects, intelligent factory, information security, additive manufacturing, etc. We currently lead several projects in H2020. For example, Unimetrik coordinates Adalam, a project in which it is

developing and certifying a system of adaptive laser micromechanization and deep measurement to solve various industrial problems.

We are also part of BeinCPPS, a project of the European I4MS initiative whose objective is to simplify the way to incorporate physical cyber systems into real production systems.

BOOST4.0 led by Asociación Innovalia and coordinated by CARSA is one of the most important projects; It is the largest European initiative in Big Data for Industry 4.0 with a budget of 20M euros and a private investment of 100M euros.