The Blechexpo international trade fair for sheet metal processing shone with product and service offerings presented by roughly 1200 exhibitors from 36 countries around the world. And thus Stuttgart was once again be distinguished as a highly practical centre for process sequences, because it represents the entire spectrum of sheet metal, pipe and profile processing in a compact format including thermal and mechanical joining and fastening technologies.

From 3rd to 6th November and with more than 150 new exhibitors and strong growth, more robots and handling systems was showcased at Blechexpo than ever before, and the same applies above all to automated thermal curing and joining technology, as well as mechanical fastening.

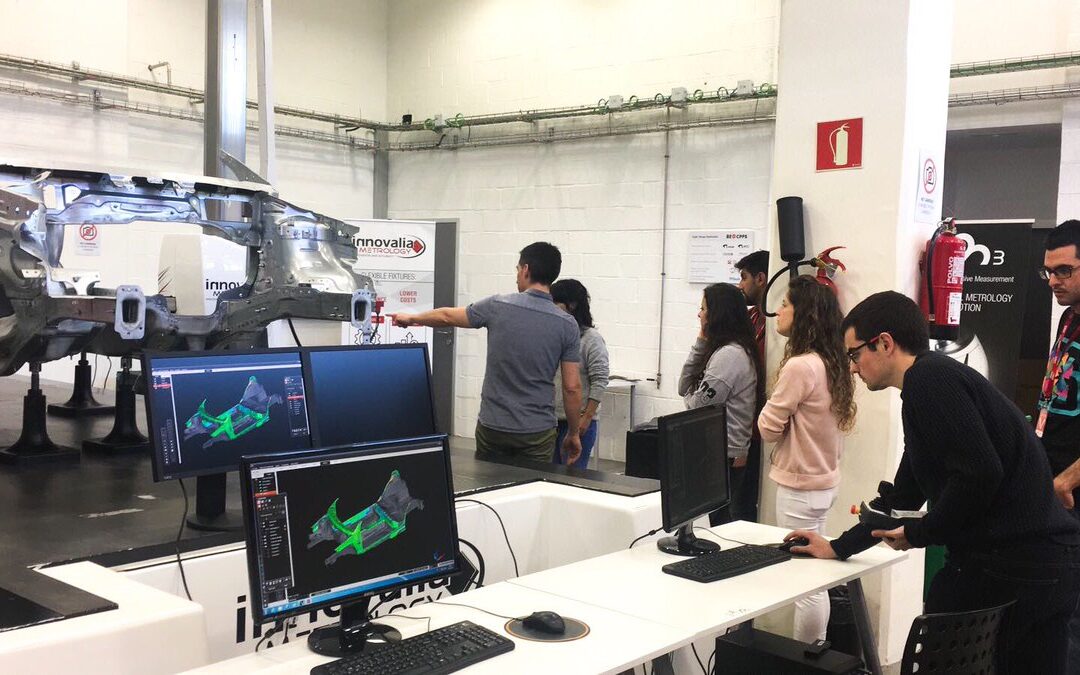

In this 13th edition, the metrological unit of Innovalia presented there the latest metrology solutions and products during these trhree and received a nnotorious and constant affluence of visitants. Innovalia Metrology presented M3 portable, a high precision standalone 3D scanning system, equipped with M3 platform (Multisensor Massive Measurement), perfect to optimize the measurement processes in a natural and efficient way, with the optical sensor Optiscan, whose unique design allows the integration into any system for both laboratory and in-line manufacturing, and with Tetracheck, the most effective and innovative verification system for your coordinate measurement machine in just 5 minutes.

With the complementary issues of sheet metal, pipe and profile processes plus joining and fastening, the trade fair covered the overall process sequence from commercial fabrication right on up to industrial production. More and more product diversity with increasing numbers of variants on the one hand, as well as smaller lot quantities and quick changeovers on the other hand, necessitate maximised flexibility – on the whole and where the details are concerned too – namely with regard to equipment, utilisation, applications and changeovers.