The International Manufacturing Technology Show (IMTS) is one of the biggest industrial trade shows in the world and will be the place where Innovalia Metrology demonstrate our new cutting edge metrology technology.

Our metrological unit, thus, will be placed in the E-4163 booth, located in East Building of the fairground in McCormick Place, Chicago, from 12 to 17 September.

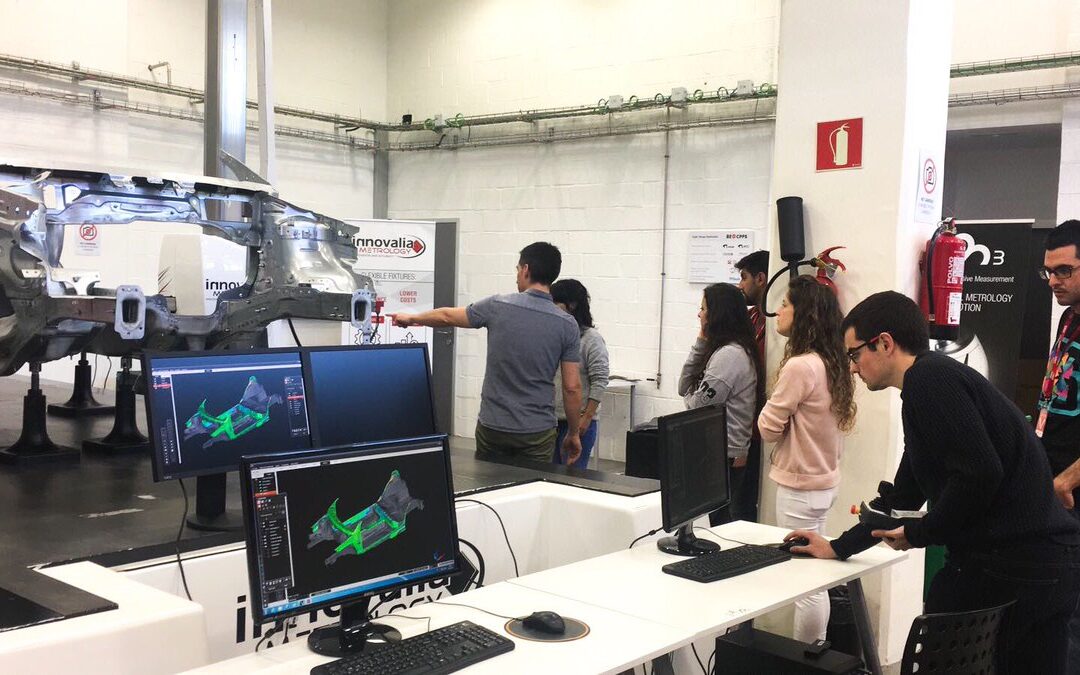

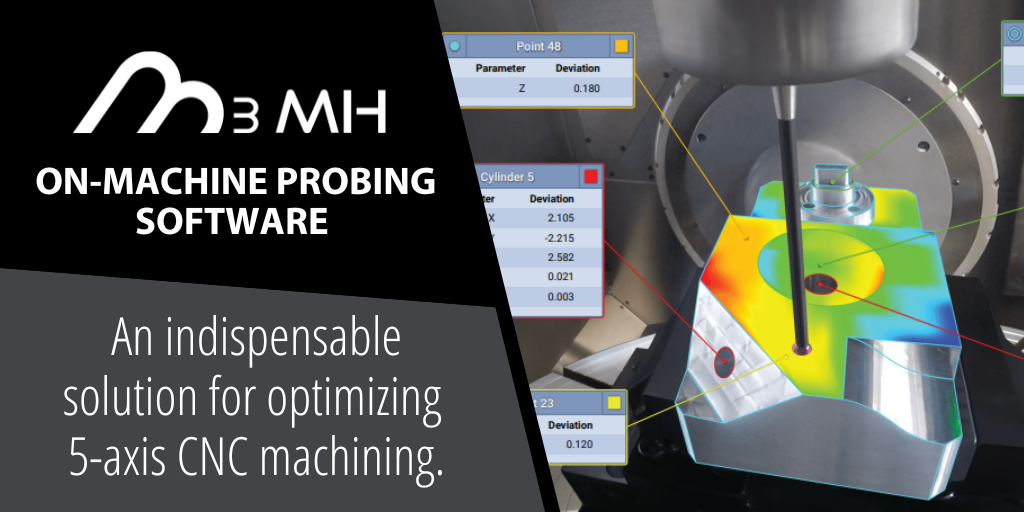

We will present our high tech machinery based on a new hybrid measurement system (M3 Hybrid) that combines the classical technique of touch probe measurements and an Optiscan optical sensor. This unique hybrid design allows the integration into any system, for both laboratory and in-line manufacturing, with high precision and speed. “The measuring process is increasingly the base for steering all manufacturing” said Jesús de la Maza, CEO at Innovalia Group.

As in every Industry 4.0 scenario, software is increasingly becoming the main focus. Our goal is clear. “With our M3 Software, we want to achieve the integration in a single workflow to increase our customers’ efficiency.” Designed specifically for in-line inspection, M3 can handle large volumes of dimensional information, obtaining accurate digital copies of the parts.

As de la Maza explained further, “through our massive M3 multiresolution data system, we can make high density measurements for large components that can create point clouds of over ten million points per measured piece.”