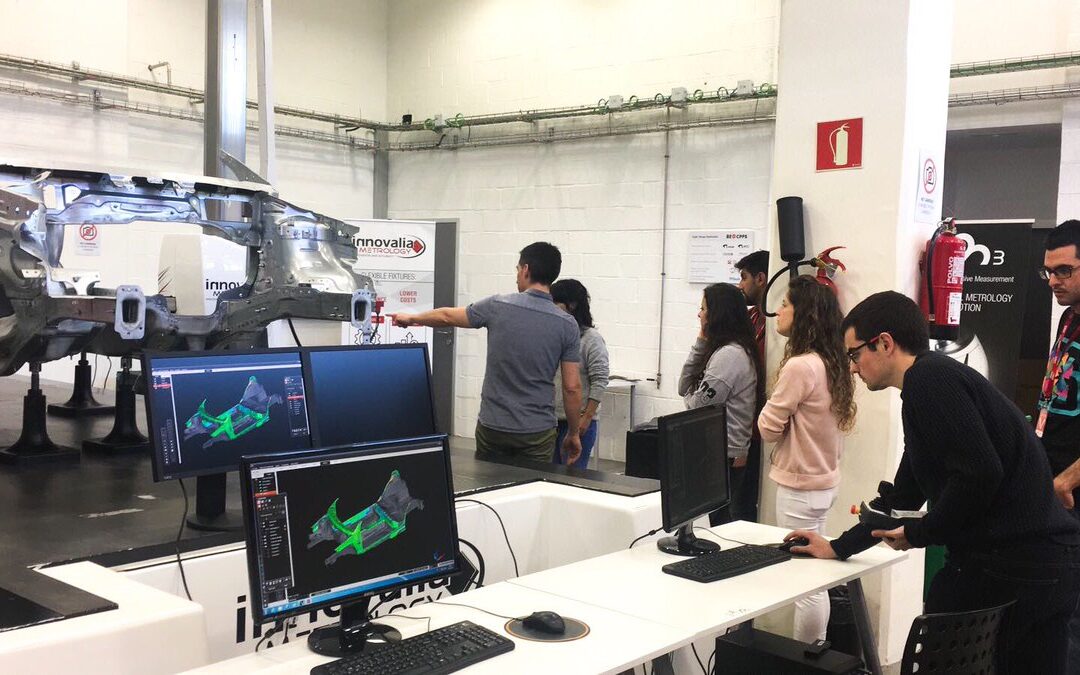

What is the connection of the measurement techniques with the change towards the new smart factories?

The future of manufacturing is what we call digital transformation, whose central element is data, which we are obtaining every day, minute by minute, in all of the processes and products. Metrology, specifically the dimensional, has to respond to that need.

Is Industry 4.0 then a reality that can be implemented?

Sure! Industry 4.0 is not a consequence of the Industry 3.0 but is something inevitable in a world where digital transformation is taking place in all areas. In the first industrial revolution, we managed to control energy, in the second one, productivity and in the third, robotics. In this fourth industrial revolution, two other elements are added: efficiency and sustainability.

Are companies able to introduce these factors?

Not all the industry is in the same starting point, although the quality seems to be exceeded, some industries have been not introduced to efficiency or sustainability. But modern industry in the other hand can be attacked because technology gives us the tools. That’s where we have the opportunity.

“The competitiveness of the manufacturing companies goes through the efficient management of two parallel flows: the physical flow of materials and components throughout the procurement, processing, manufacturing and distribution processes and the digital data flow, information and knowledge in the different phases of the product cycle – design, prototypes, production launch and series production.

The European reindustrialization initiatives (Industry 4.0 in Germany, Factories of the Future in the European Union) are committed to the massive digitization of industrial processes.

Each industrial revolution has required the development of metrology tools and methods that have made it possible. Industry 1.0 emerged from empiricism and the scientific vision of reality, extending the use of mechanical metrology instruments that allowed obtaining objective data of products and processes. Industry 2.0 involved the introduction of more advanced manufacturing processes such as the chain production. In order to increase productivity, more sophisticated measurement technologies were developed allowing a greater performance of the manufacturing processes. Industry 3.0 was “The revolution of automation” and the CMM machine concept emerged as an automated element that combines sensorics, electronics, mechanics and programmable logic. Now, Industry 4.0 offers digitization and virtualization of the manufacturing industry, through technologies such as digitized. The concept of Metrology has changed and will change much more. We are living the beginning of a radical change in the way of capturing, analyzing and integrating product information and industrial manufacturing processes; Metrology must be able to offer increasingly integrated solutions in the digital factory”

– Source: Toni Ventura at Metromeet 2018