· First of all, we would like to know your vision about the current situation of industrial metrology and the role it plays and can play in the near future.

· First of all, we would like to know your vision about the current situation of industrial metrology and the role it plays and can play in the near future.

Many of the techniques that were made in the laboratories are being incorporated into the manufacturing process and this makes the industry begin to be more competitive. If we detect a fault when the part is finished, the cost of the error is very large.

The deployment of metrology resources, methods and processes is the key for the industry to reach the levels of productivity, quality and efficiency required in today’s markets. It can only be improved if it can be measured, and metrology is the practice of this concept. Industrial metrology allows to obtain information and knowledge about industrial products and processes, to control, improve and optimize them.

· What is your opinion about the introduction of metrology in productive processes and what improvements and difficulties do you see in this process?

If we detect a fault when the part is finished, the cost of the error is very high. However, production could be reduced if we verify in the previous phases. The introduction of metrology equipment into the process is something vital and it will be for companies that use metrology systems to evolve towards an Industry 4.0. We are at the beginning of a radical change in the way we capture, analyze and integrate information about industrial manufacturing products and processes; Metrology must be able to offer increasingly integrated solutions in the digital factory.

Thanks to information and communication technologies, transformation is taking place in all areas of human activity and is crucial for the industry. Metrology products and solutions must also be interconnectable with intelligent processing capacity, to store and process large volumes of data. The key element of this equation is the standardization of digital components and exchange formats, ensuring that any equipments can interoperate with other equipments and systems.

In this sense, having a real contribution to the evolution of the Industry is one of the advantages by the Innovalia Group in order to develop a metrological technology better adapted to the needs of the companies.

· What opinion do you have regarding the large amounts of data handled today in the measurement processes?

It is increasing evident that the work and management with digital parts facilitate and improve the production process. Having a file of our digital parts, we can resort to them, observe failures and compare the result of a production in a realistic way.

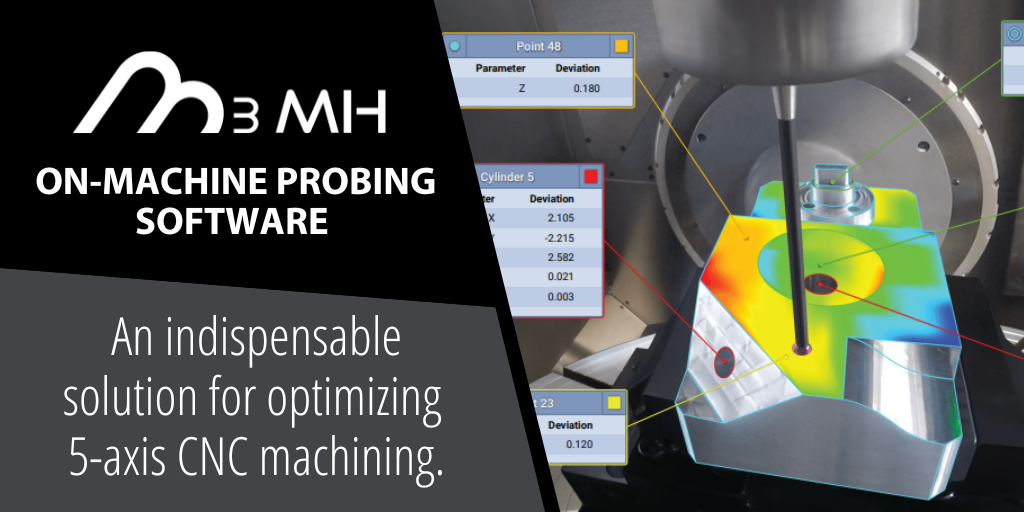

Every measurement process 4.0 needs a software with a capacity of concrete data management. Therefore, M3 Software, our measurement software is prepared to analyze large amounts of data and work with IoT sensors allowing to import data with different sensors and different devices.

· Will the optical sensors finally prevail or will both methods coexist depending on the characteristics of the measurement?

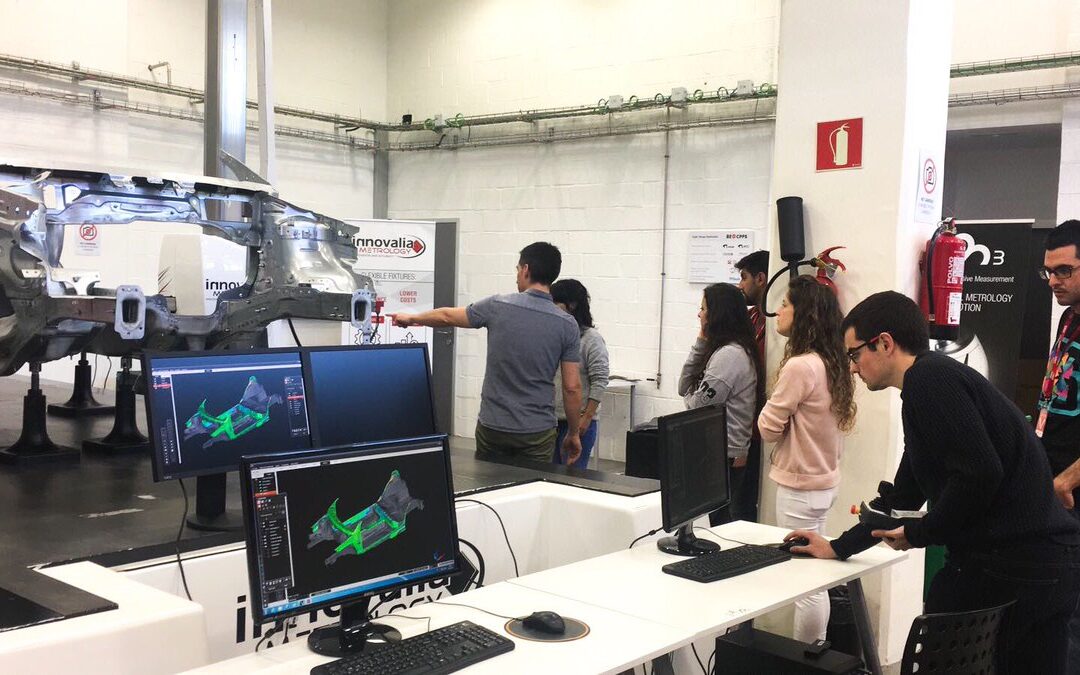

Innovalia Metrology (Datapixel) has been designing, manufacturing and commercializing the Optiscan sensor for 18 years, as well as solutions for quality control in the manufacture of automotive and aeronautical components. Optical scanners allow to capture and control the dimensions and 3D shapes of various parts, such as metal stamping components that are part of the bodywork, carbon fibre parts or wings of aircraft, mechanized parts of engines, turbine blades of engines or plastic parts.

Scanners have a great international acceptance and that allow manufacturing companies to perform dimensional inspections with micron precision. There is a large number of companies that will continue to capture data through contact, but in our case, Optiscan offers a much more complete capture and in much shorter time. It is clear that the optical sensors can offer more improvements in production; something we have been betting on for a long time and at this moment,it is recognized by the industry.

· Innovalia Metrology develops measurement equipments. What can you tell us about its accuracy and metrological traceability? Do you have an accredited calibration laboratory?

Unimetrik is an accredited calibration laboratory that allows us to have highly competitive equipment in the market, not only for price but also for assurance of traceability and equipment status throughout the measurement process. Unimetrik has the METRINET tool that supports all of its clients in monitoring the verification of their equipment, tools and patterns.

· How does Innovalia contemplate the evolution towards the 4th industrial revolution and how does it affect its business strategy?

Innovalia already put in value the need to bet on the facilitating technologies when still nobody talked about Industry 4.0.

Each industrial revolution has required the development of tools and methods of metrology that have made it possible. Industry 1.0 grew out of empiricism and the scientific vision of reality, extending the use of mechanical metrology instruments that allowed obtaining objective data of products and processes. Industry 2.0 involved the introduction of more advanced manufacturing processes such as mass production. In order to increase productivity, more sophisticated measurement technologies were developed allowing a greater performance of the manufacturing processes. Industry 3.0 was “The revolution of automation” and the CMM machine concept emerged as an automated element that combines sensorics, electronics, mechanics and programmable logic. Finally, Industry 4.0 offers the leap to digitization and virtualization of the manufacturing industry. The combination of OptiScan and M3Software makes it possible. The integration of these technologies with other digital systems leads us to the digitalization of processes. Industry 4.0 is an idea, a concept that must be “landed” on existing processes and products; and of course in Innovalia, we are already investing efforts in contributing to make it a reality.