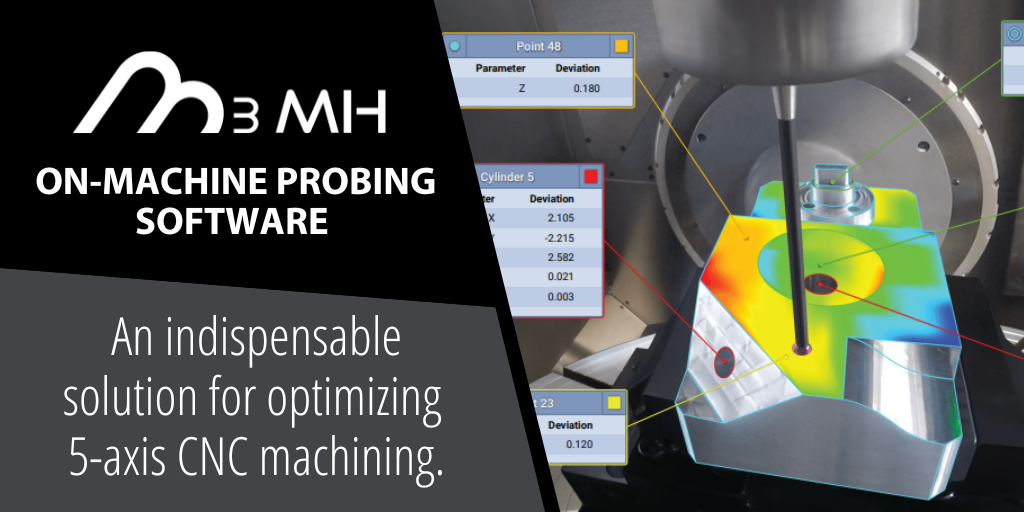

An indispensable solution for optimizing 5-axis CNC machining.

Manufacturers are increasingly seeking options to optimize production processes and reduce operational and investment costs. In many cases, additional investment is required to acquire external metrology machines or tools for quality control of produced parts. While these systems are indispensable for many inspections, their usage can be reduced through the implementation of in-process measurement solutions. In this regard, Innovalia Metrology offers M3MH, the machine tool measurement software, as the solution that encompasses three functionalities to maximize the performance of machining centers: piece set-up with the possibility of iterative alignments, in-process measurement, and machine verification.

M3MH offers a wide range of possibilities within the machining center itself, ranging from simple and fast measurement of a single point to the collection of point clouds and analysis of complex parts. Moreover, the software enables data capture, measurements, and visualization in a broad spectrum that is fully compatible with dedicated devices such as coordinate measuring machines or measurement arms.

All the functionalities of M3MH significantly reduce manufacturing time, enhance traceability and quality of both the production process and the manufactured parts, and ensure complete control of the entire machining process. The reduction in tooling costs and adaptive manufacturing make this product a success story and a technological advancement for machining companies, particularly for manufacturers dealing with large and complex parts, where proper off-machine inspection is not feasible or where the preparation time and cost of moving the parts are high.

From a technical standpoint, M3MH provides seamless integration with machine control. Additionally, its intuitive interface allows you to perform the following functions:

- Axis check: verification of rotary axes

- Machine check: verification of machine volume

- M3MH Set up: piece alignment

- M3MH Measurement: pre, post, and in-process measurement.

M3MH, a software certified by accredited entities, incorporates advanced Industry 4.0 concepts to meet the needs of manufacturers, ultimately achieving the primary goal of producing accurate parts. Discover more information about M3MH software and Innovalia Metrology on their website at www.innovalia-metrology.com.